Zjp roots vacuum pump

Description

ZJ and zjp roots vacuum pump is a kind of rotary variable volume vacuum pump, also known as mechanical booster pump. It is one of the main pumping equipment to obtain medium and high vacuum at present. Its working principle is similar to roots blower. It uses two "8" shaped rotors to rotate synchronously in the pump shell to complete suction and exhaust.

The difference between zjp roots vacuum pump with relief valve and ZJ Roots vacuum pump is that the inlet and outlet of zjp pump are connected, and a self weight valve is vertically installed on the channel. Its function is to keep the pressure difference between the exhaust port and the inlet port within a controllable value, which is the maximum allowable pressure difference when the pump operates reliably. Therefore, this kind of valve is actually an overload automatic protection valve.

ZJ and zjp roots vacuum pumps are widely used in vacuum degassing, vacuum melting, vacuum surface treatment, low-density wind tunnel test and manufacturing of electrical equipment and vacuum freeze-drying equipment in metal and non-metal material industry. After being configured in series with water ring vacuum pump and liquid ring vacuum pump, the pumps are more suitable for vacuum polymerization, reaction, decomposition and food industry in chemical industry Vacuum distillation, vacuum drying, vacuum crystallization and other technological processes.

Main features

(1) It can pump at a wide pressure range (1 ~ 1.3 × 102 PA).

(2) There is no oil in the pump cavity to avoid oil vapor pollution of the vacuum system.

(3) Small vibration and low noise.

(4) The mechanical friction loss is small, so the driving power is small.

(5) Easy to maintain and repair, low cost, long life.

(6) Suitable for sudden venting of vacuum system.

(7) Condensable gas can be pumped out.

(8) Can not be used alone, must be equipped with a front pump. It is not allowed to start under atmospheric pressure. It can only be started when the front pump pumps the inlet pressure of roots pump to the allowable starting pressure. Before the pump is generally sealed mechanical pump, liquid ring vacuum pump, such as water ring pump and oil ring pump.

(9) Unique processing technology is adopted, and the interchangeability of parts is good.

(10) It can be used for electroless nickel plating and Hastelloy treatment on the gas flow part and all stainless steel material, which can resist all kinds of acid, alkali and organic solvent corrosion.

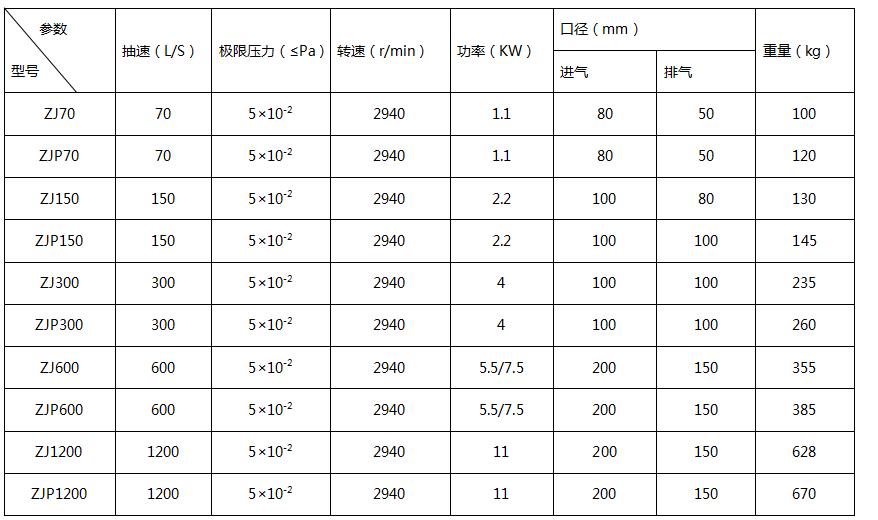

Performance parameter table

Note:

1. The ultimate vacuum refers to the lowest value of the stable air partial pressure measured at the pump inlet with a compression vacuum gauge after full pumping without any additional container and no air intake.

2. Each performance in the above table is obtained under the condition of using the recommended front stage vacuum pump. Users can choose different front stage vacuum pumps according to different situations, but the main performance indexes will change.

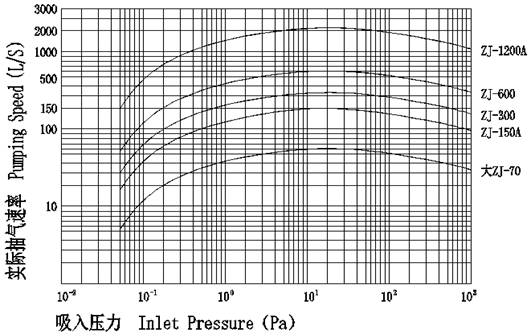

characteristic curve